Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

In today's competitive manufacturing landscape, the significance of injection molding tooling cannot be overstated. A recent report by Grand View Research indicates that the global injection molding market is expected to reach $370 billion by 2027, highlighting the growing demand for advanced tooling solutions. Understanding the intricacies of injection molding tooling not only optimizes production efficiency but also enhances product quality and reduces costs. By leveraging state-of-the-art tooling strategies, manufacturers can significantly decrease cycle times and increase production rates. Furthermore, a study by MarketsandMarkets reveals that investment in injection molding tooling can lead to a 20-30% reduction in overall manufacturing costs. As industries evolve, mastering injection molding tooling has become essential for businesses seeking to maintain a competitive edge and drive transformative success in their manufacturing processes.

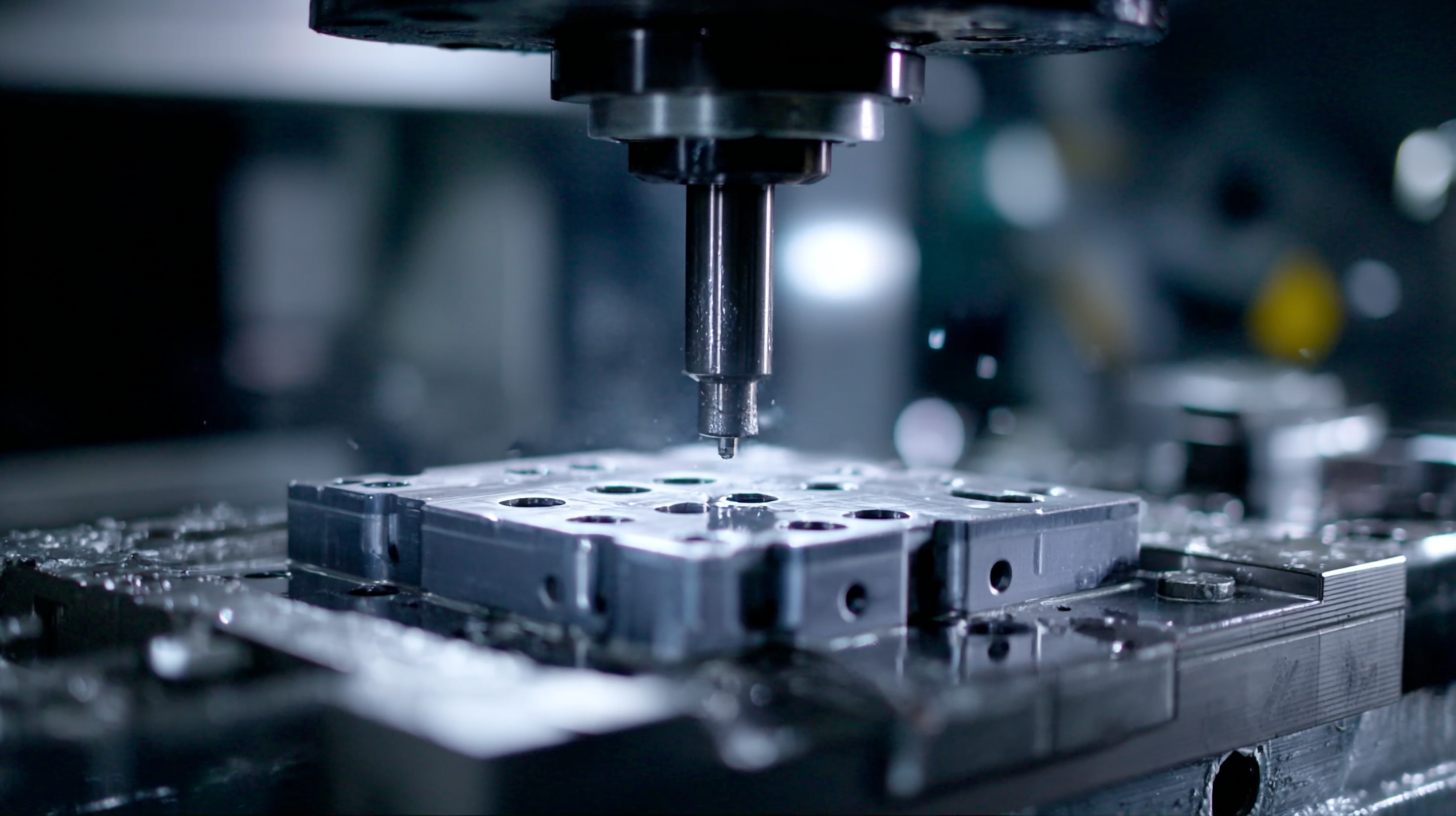

The Role of Injection Molding Tooling in Streamlining Production Processes

Injection molding tooling plays a crucial role in enhancing the efficiency of production processes across various manufacturing sectors. According to a report by Freedonia Group, the global injection molding market is expected to reach $382 billion by 2025, highlighting the increasing dependence on this technology for high-volume production. The design and quality of injection molding tools directly impact cycle times, material utilization, and overall operational costs. As noted by the Plastics Industry Association, optimizing tooling can lead to a reduction in production time by up to 25%, allowing manufacturers to respond more quickly to market demands and reduce lead times.

Moreover, advances in tooling technology, such as the integration of computer-aided design (CAD) and simulation software, have significantly transformed how manufacturers approach production. These innovations enable the analysis of complex designs and predict potential issues before they arise, thus further streamlining the manufacturing process. A study from Deloitte indicates that manufacturers leveraging modern tooling techniques can achieve a 30% increase in productivity. Therefore, understanding and investing in high-quality injection molding tooling can lead to substantial improvements not just in product quality but also in overall manufacturing success.

Key Factors Influencing the Design of Efficient Molding Tools

Understanding the key factors influencing the design of efficient molding tools is essential for achieving manufacturing success through injection molding. One of the primary considerations is material selection. Different polymers respond uniquely to heat and pressure, so choosing the right material for the specific application can significantly affect tool longevity and the quality of the finished product. Additionally, the incorporation of advanced materials in tool design can improve durability and reduce maintenance costs, leading to greater operational efficiency.

Another significant factor is the design of the cooling system within the mold. Efficient cooling directly impacts cycle times and product quality. A well-designed cooling system allows for uniform temperature distribution, minimizing warpage or defects in the molded parts. Moreover, the geometric design of the mold itself, including features like draft angles and venting, plays a crucial role in ensuring easy part release and optimizing flow characteristics. By focusing on these key design elements, manufacturers can enhance productivity and ultimately transform their injection molding processes.

Innovative Materials and Technologies in Injection Molding Tooling

Injection molding tooling is at the forefront of manufacturing innovation, particularly through the integration of advanced materials and technologies. As per a recent report by MarketsandMarkets, the global injection molding market was valued at approximately $260 billion in 2019 and is projected to reach $370 billion by 2024, growing at a CAGR of 7.6%. This growth is largely driven by the increasing demand for lightweight and durable materials that enhance production efficiency and product performance. Incorporating innovative materials like reinforced plastics and bio-based resins not only improves the material properties but also caters to the rising need for sustainable manufacturing practices.

Technological advancements also play a crucial role in the evolution of injection molding tooling. The adoption of additive manufacturing and 3D printing for tooling has revolutionized the design and production process, reducing lead times and costs. According to a study by PwC, 92% of manufacturers believe that 3D printing will be instrumental in their supply chain strategies over the next five years. Furthermore, the implementation of Industry 4.0 technologies, including IoT and AI, allows for real-time monitoring and predictive maintenance of molds, significantly enhancing operational efficiency. By leveraging these innovative materials and technologies, manufacturers can not only optimize their production processes but also adapt to changing market demands swiftly.

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

| Material Type | Typical Applications | Advantages | Considerations |

|---|---|---|---|

| ABS | Consumer electronics, toys, automotive parts | Durability, impact resistance, ease of machining | Can be sensitive to UV light, can warp under heat |

| Polypropylene | Containers, automotive components, medical supplies | Chemical resistance, low density, good fatigue resistance | Lower rigidity, can be affected by certain solvents |

| Nylon | Textiles, automotive parts, machinery | High strength, good wear resistance, elasticity | Can absorb moisture, may require drying before processing |

| Polycarbonate | Safety glasses, automotive headlamp covers, electronic components | Exceptional toughness, transparency, heat resistance | Scratch-sensitive, can be costly |

| PS (Polystyrene) | Packaging, disposable cutlery, insulation | Low cost, ease of molding, good rigidity | Brittle, limited temperature resistance |

Cost-Effectiveness of Investing in Advanced Injection Molding Tools

Investing in advanced injection molding tooling is becoming increasingly cost-effective for manufacturers aiming to enhance productivity and reduce waste. High-quality molds not only improve the precision of the products manufactured but also significantly decrease cycle times. This results in lower production costs in the long run, making it a smart investment for businesses that want to stay competitive in the ever-evolving manufacturing landscape.

**Tip:** When considering new tooling investments, assess your current production needs and future growth potential. Advanced tooling can accommodate a wider range of materials and complexities, enabling manufacturers to expand their product offerings without the need for frequent equipment changes.

Moreover, the demand for specialized metal powders in additive manufacturing is gaining momentum, which can also impact injection molding processes. As manufacturers explore integrating various materials into their production lines, understanding the nuances of tooling becomes essential. Efficient tooling design supports the compatibility with diverse materials, leading to enhanced product quality and market responsiveness.

**Tip:** Regularly evaluate the latest advancements in material technology and tooling designs. Keeping abreast of these trends can help optimize your manufacturing approach and lead to innovative product solutions that meet market demands.

Case Studies: Transformative Impacts of Tooling on Manufacturing Outcomes

Understanding the role of injection molding tooling is pivotal in enhancing manufacturing outcomes. For instance, a study by the Plastics Industry Association found that companies that invested in advanced tooling technologies saw a 15-20% reduction in cycle times, directly contributing to increased production efficiency and lower operational costs. These improvements allow manufacturers to meet the growing demand for high-quality plastic products while maintaining competitive pricing.

Another compelling case is the automotive industry, where precise tooling has led to significant enhancements in product quality and consistency. According to a report by Grand View Research, the automotive sector's adoption of innovative injection molding tools has resulted in a 25% increase in output quality over the last five years. By utilizing cutting-edge materials and designs, manufacturers can create components that not only meet stringent safety standards but also support the growing trend of lightweight vehicles, ultimately driving more sustainable practices in production.

Related Posts

-

Common Issues in Achieving the Best Plastic Injection Mold Design

-

Essential Checklist for Effective Mold Design in Injection Molding Processes

-

In Depth Comparison of Plastic Injection Mold Tooling Techniques and Their Industry Impact

-

7 Essential Tips for Optimizing Your Mold Manufacturing Process

-

Unlocking the Secrets of Best Plastic Manufacturing with Comprehensive Technical Guidelines

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes