2025 Top 5 Innovations in Injection Moulding Process for Efficient Production

The injection moulding process has revolutionized the manufacturing landscape by offering unparalleled efficiency and versatility in producing complex plastic components. As industries continue to evolve, the demand for innovative solutions to enhance production efficiency becomes increasingly critical. In 2025, we anticipate significant advancements that will further refine the injection moulding process, addressing both sustainability and productivity challenges faced by manufacturers.

With a focus on technological integration and material innovation, the top five innovations set to transform the injection moulding process will not only improve throughput but also reduce waste and energy consumption. These innovations herald a new era where precision and efficiency coalesce, ensuring that manufacturers can meet the demands of a rapidly changing market while adhering to environmental considerations. As we explore these groundbreaking developments, it becomes clear that the future of the injection moulding process will be characterized by smart design, enhanced automation, and sustainable practices, ultimately leading to optimized production outcomes.

Advancements in Smart Injection Moulding Technologies for Enhanced Productivity

The injection moulding industry is witnessing a significant transformation with advancements in smart technologies aimed at enhancing productivity. As reported by Mordor Intelligence, the global injection molding market is projected to grow at a CAGR of 4.9% from 2023 to 2028, indicating a rising demand for innovative solutions. This growth is driven largely by the integration of AI and IoT in manufacturing processes, allowing for real-time monitoring and optimization. Smart injection moulding machines can now collect and analyze vast amounts of data, leading to improved cycle times and reduced waste, while ensuring consistent product quality.

To leverage these advancements effectively, manufacturers should consider implementing predictive maintenance algorithms. These tools can foresee equipment failures before they occur, substantially decreasing downtime. According to a study by Aberdeen Group, organizations that adopted predictive maintenance have reported a 30% reduction in maintenance costs and a 30% increase in overall equipment effectiveness.

Additionally, embracing automation is crucial for efficiency. Robotics are increasingly utilized in injection moulding to automate complex tasks, enhancing speed and precision. For instance, a report from Technavio highlights that companies employing robotics in their production lines can achieve up to a 20% increase in throughput. As the industry evolves, these smart technologies will be pivotal in driving forward the future of efficient production in injection moulding.

Eco-Friendly Materials: The Future of Sustainable Injection Moulding Practices

The evolution of injection moulding practices is increasingly leaning towards sustainability, with eco-friendly materials leading the charge for a more responsible production approach. These innovative materials not only reduce the environmental impact associated with traditional plastics but also offer comparable performance and versatility. Biodegradable polymers and recycled materials are becoming integral to various industries, reflecting a growing commitment to reducing waste and conserving resources.

Incorporating eco-friendly materials into the injection moulding process demands a rethinking of design and manufacturing practices. This transition involves adapting machinery and techniques to accommodate new material properties, ensuring efficiency without compromising quality. As companies invest in research and development, they uncover novel bio-based alternatives that meet stringent performance criteria while being environmentally benign. The focus on sustainable injection moulding is not just a trend but is quickly becoming a necessity for businesses aiming to align with global sustainability goals and consumer preferences.

Automation and Robotics: Redefining Efficiency in Injection Moulding Processes

The integration of automation and robotics in injection moulding processes represents a pivotal shift towards achieving unparalleled production efficiency. As manufacturers strive to meet the increasing demand for precision and speed, employing advanced robotic systems in the injection moulding cycle allows for enhanced consistency and quality control. Automated systems facilitate real-time monitoring and adjustments, minimizing the risk of human error and optimizing machine performance.

Moreover, robotics streamline material handling and product assembly, significantly reducing cycle times. Intelligent robotic arms can swiftly manipulate complex components and perform intricate assembly tasks, which in turn allows for greater flexibility in production lines. By leveraging automated solutions, companies can not only boost their output but also adapt to changing market demands with ease, maintaining a competitive edge in the global landscape of manufacturing. The future of injection moulding is thus decidedly aligned with advancements in automation, heralding an era marked by increased efficiency and innovation.

2025 Top 5 Innovations in Injection Moulding Process for Efficient Production

| Innovation | Description | Benefits | Implementation Timeframe |

|---|---|---|---|

| Smart Automation | Integration of AI and machine learning for real-time monitoring and adjustments. | Increased production speed and reduced defects. | 2023-2025 |

| Robotic Process Automation | Use of advanced robotics for part handling and assembly. | Improved precision and reduction in labor costs. | 2024 |

| IoT Integration | Connected devices for enhanced data collection and analysis. | Better decision-making through improved insights. | 2023 |

| Energy-efficient Machines | New generation of machines designed to minimize energy consumption. | Cost savings and environmental benefits. | 2025 |

| Advanced Materials | Development of new material formulations for greater flexibility and strength. | Enhanced product performance and durability. | 2023-2024 |

Innovative Cooling Solutions for Faster Cycle Times in Injection Moulding

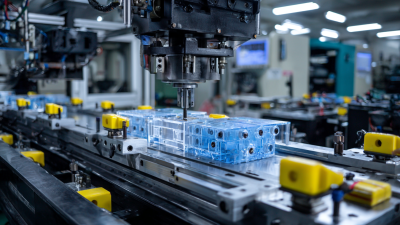

In the world of injection moulding, innovative cooling solutions are paving the way for faster cycle times, significantly enhancing production efficiency. Traditional cooling methods often leave much to be desired, resulting in longer wait times and increased energy consumption. However, advancements such as conformal cooling channels and enhanced heat exchangers are revolutionizing the cooling process. These technologies allow for more uniform temperature distribution, ensuring that components cool evenly without warping or deforming, which ultimately leads to a higher-quality final product.

Tips for implementing these cooling innovations include regularly assessing your current cooling setup and identifying areas where modifications could enhance efficiency. For instance, integrating simulation software can help visualize heat flow and cooling patterns, allowing you to optimize your mould design proactively. Additionally, consider investing in materials that have improved thermal conductivity to complement your advanced cooling systems, as this can further decrease cycle times and improve overall production speed.

It's also essential to train your production team on the new technologies and their benefits. Understanding the science behind cooling solutions enables operators to troubleshoot effectively and maintain efficiency. Regular workshops or training sessions can keep your team updated on best practices, fostering a culture of continuous improvement in injection moulding production.

Real-Time Data Analytics: Optimizing Injection Moulding Operations for Superior Quality

Real-time data analytics is revolutionizing the injection moulding industry by enhancing operational efficiency and product quality. According to a recent report by Grand View Research, the global injection moulding market is projected to reach $419.8 billion by 2028, highlighting the growing need for innovative solutions to meet increasing production demands. By integrating data analytics into their operations, manufacturers can monitor key performance indicators in real time, enabling them to swiftly identify and rectify any anomalies in the production process.

Additionally, a study conducted by McKinsey & Company indicated that companies leveraging data analytics in manufacturing are likely to achieve productivity gains of 15-20%. By utilizing predictive analytics, manufacturers can foresee equipment failures, optimize maintenance schedules, and thereby minimize downtime. This proactive approach not only enhances operational continuity but also ensures superior quality control, resulting in reduced scrap rates and improved customer satisfaction. Implementing real-time data analytics in injection moulding operations is not merely an option; it has become a crucial factor for businesses aiming to thrive in an increasingly competitive landscape.

2025 Innovations in Injection Moulding Process

Related Posts

-

Exploring Innovative Applications of Thermoplastic Injection Molding in Modern Manufacturing

-

What is the Impact of Medical Injection Molding on Healthcare Innovation and Patient Outcomes

-

Why Understanding Injection Molding Tooling Can Transform Your Manufacturing Success

-

Maximizing Efficiency in Plastic Injection Mold Tooling for High Volume Production

-

2025 How to Choose the Best Plastic Injection Tooling for Your Production Needs

-

Leading Chinese Factory Delivers Unmatched Excellence in Medical Injection Molding