Innovative Examples of Automotive Injection Molding Applications in the Industry

In today's rapidly evolving automotive industry, manufacturers are continually seeking innovative solutions to enhance efficiency, reduce costs, and improve product quality. One such solution that has gained significant traction is automotive injection molding. This versatile manufacturing process allows for the creation of complex and precise components that are integral to modern vehicles, from the intricate dashboard elements to lightweight structural parts.

As the industry moves towards greater sustainability and advanced material usage, the applications of automotive injection molding are expanding, showcasing its ability to meet the ever-increasing demands for performance and functionality. In this blog, we will explore several innovative examples of automotive injection molding applications that not only highlight its capabilities but also underscore its critical role in shaping the future of automotive design and manufacturing.

As the industry moves towards greater sustainability and advanced material usage, the applications of automotive injection molding are expanding, showcasing its ability to meet the ever-increasing demands for performance and functionality. In this blog, we will explore several innovative examples of automotive injection molding applications that not only highlight its capabilities but also underscore its critical role in shaping the future of automotive design and manufacturing.

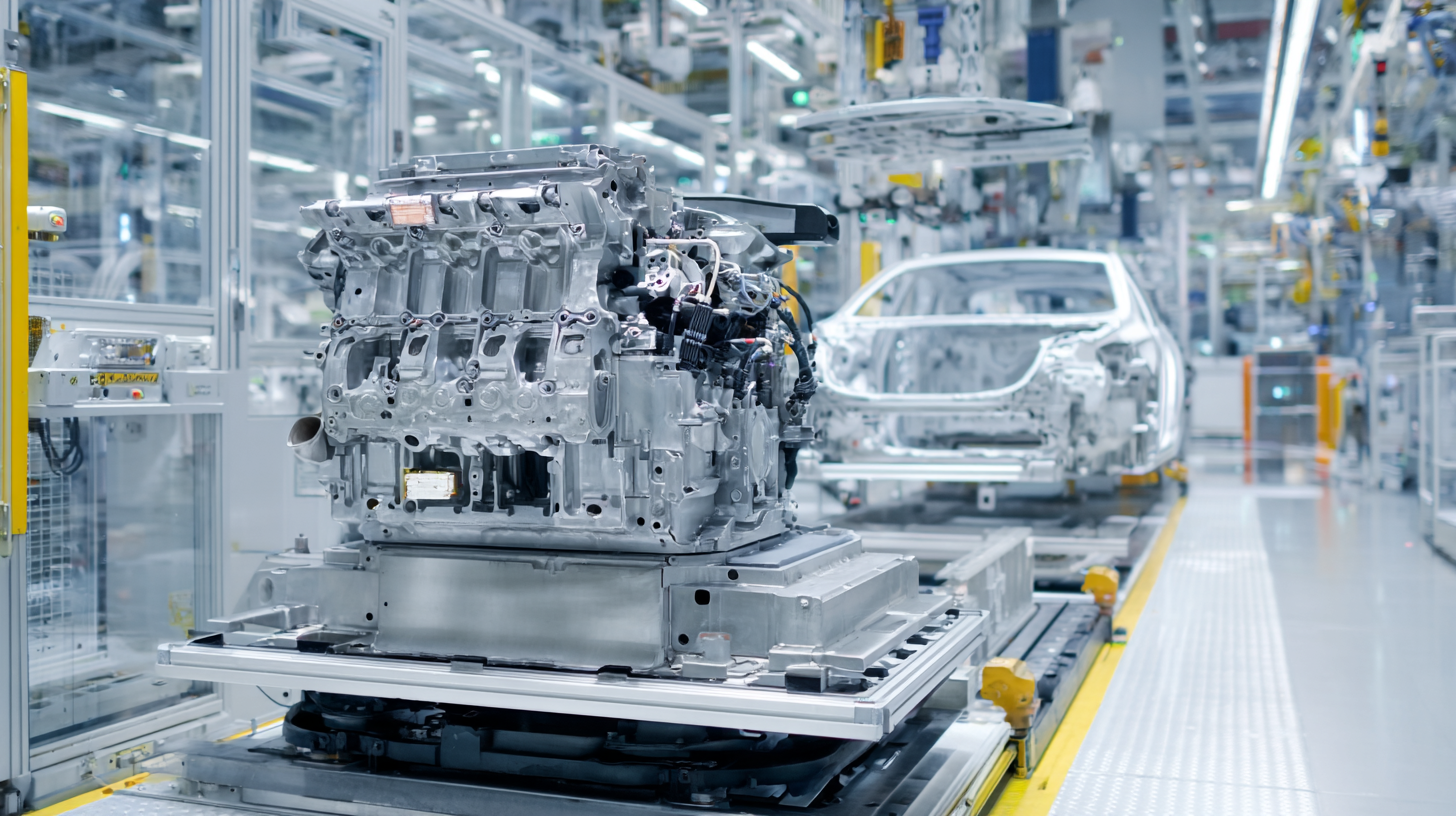

Revolutionizing Car Components: Key Innovations in Injection Molding

The automotive industry is experiencing a transformative phase, thanks in part to innovative applications of injection molding technology. This advanced manufacturing process has emerged as a key player in revolutionizing car components, allowing for the production of lightweight, durable parts that enhance vehicle performance and efficiency. One significant innovation is the development of complex geometries that would have been challenging or impossible to achieve with traditional manufacturing techniques. This not only reduces material waste but also streamlines the production process, leading to cost savings for manufacturers.

The automotive industry is experiencing a transformative phase, thanks in part to innovative applications of injection molding technology. This advanced manufacturing process has emerged as a key player in revolutionizing car components, allowing for the production of lightweight, durable parts that enhance vehicle performance and efficiency. One significant innovation is the development of complex geometries that would have been challenging or impossible to achieve with traditional manufacturing techniques. This not only reduces material waste but also streamlines the production process, leading to cost savings for manufacturers.

Moreover, advancements in materials used in injection molding are propelling the industry forward. For instance, the integration of reinforced plastics and composite materials is enabling the production of components that can withstand higher stress and temperatures. These innovations are critical for various automotive applications, from interior trim to structural elements like brackets and supports, where strength coupled with lightweight properties is essential. As manufacturers continue to explore and implement these cutting-edge techniques, the future of automotive design looks increasingly promising, with a focus on sustainability, efficiency, and enhanced consumer experiences.

Lightweighting Strategies: How Injection Molding Reduces Vehicle Weight

The automotive industry is increasingly turning to innovative lightweighting strategies, leveraging the advantages of injection molding to reduce vehicle weight. By using advanced materials like continuous fiber-reinforced thermoplastics, the market is projected to grow from $103.74 million in 2024 to $146.75 million by 2032, marking a 4.5% increase. This shift towards lighter materials not only enhances fuel efficiency but also meets stringent environmental regulations.

One of the prominent examples of injection molding in automotive applications is the use of hybrid components, blending plastic and metal to optimize strength and weight. This approach was recently highlighted during a technology showcase, where various innovations were demonstrated, indicating a strong push in developing low-carbon solutions within the industry. As the sector evolves, companies must prioritize the integration of these materials into their designs to stay competitive.

**Tip:** When designing for lightweighting, consider the synergistic effects of combining different materials. Integrating injection-molded parts can significantly lower production costs and improve vehicle performance. Keeping abreast of emerging materials and methods will be crucial in mastering this ever-evolving sector.

Innovative Examples of Automotive Injection Molding Applications: Weight Reduction

Sustainable Practices: Eco-Friendly Materials in Automotive Injection Molding

The automotive industry is increasingly focusing on sustainable practices, particularly through the use of eco-friendly materials in injection molding. Bio-polypropylene, for instance, is gaining traction with a projected market value of USD 1,160.28 million by 2029. This bio-based material not only offers a lower carbon footprint compared to traditional polypropylene, but it also meets the growing consumer demand for sustainable products. Utilizing such materials can significantly enhance the environmental performance of automotive components.

When incorporating sustainable materials into your production, consider these tips: Firstly, invest in research to identify biodegradable and recycled options that meet industry standards. Secondly, engage with suppliers who prioritize eco-friendly practices and materials, ensuring a responsible procurement chain. Lastly, integrate recycling processes in your operations to minimize waste, ultimately contributing to a circular economy.

In addition to bio-polypropylene, the recycled thermoplastics market is witnessing robust growth, with an estimated size of USD 52.51 billion in 2023, poised to expand at a CAGR of 9.6% through 2030. This trend reflects a broader shift toward resource efficiency, encouraging manufacturers to rethink their material choices and adopt innovative technologies for waste reduction, paving the way for a greener automotive industry.

Advanced Technology: 3D Printing and Injection Molding Synergies in Auto Parts

The automotive industry is experiencing a remarkable transformation, driven by the synergy between 3D printing and injection molding technologies. This innovative combination allows manufacturers to produce complex, lightweight components that meet the rigorous demands of vehicle performance and design aesthetics. By integrating 3D printing into the injection molding process, companies can create precise molds tailored for unique auto parts, enhancing not only production efficiency but also reducing material waste.

Tips for implementation involve conducting a thorough assessment of the component requirements before proceeding with design modifications. Employing simulation software can streamline the prototyping phase, allowing for adjustments to be identified early. Additionally, invest in training for your team to ensure they are familiar with both technologies, fostering a culture of innovation.

Furthermore, it's essential to establish strong supplier relationships to ensure the timely procurement of high-quality materials. Collaborating with experts in both 3D printing and injection molding can yield insights that enhance product durability and performance. Emphasizing adaptability in production processes can position companies to better respond to the rapidly changing landscape of automotive manufacturing.

Innovative Examples of Automotive Injection Molding Applications in the Industry - Advanced Technology: 3D Printing and Injection Molding Synergies in Auto Parts

| Application Area | Material Used | Technology Synergy | Benefits | Production Efficiency |

|---|---|---|---|---|

| Dashboard Components | Polycarbonate Blend | 3D Printing Prototypes + Injection Molding | Enhanced Design Flexibility | 30% faster time-to-market |

| Fuel System Components | Glass-Filled Nylon | Injection Molding + Additive Manufacturing | Reduced Weight with Strength | 25% lower production costs |

| Exterior Trim Parts | Acrylonitrile Butadiene Styrene (ABS) | 3D Printed Molds | Cost-Effective Low-Volume Production | 40% faster cycle times |

| Interior Panels | Thermoplastic Polyurethane (TPU) | Hybrid Manufacturing Techniques | Improved Aesthetics and Durability | 20% increase in production speed |

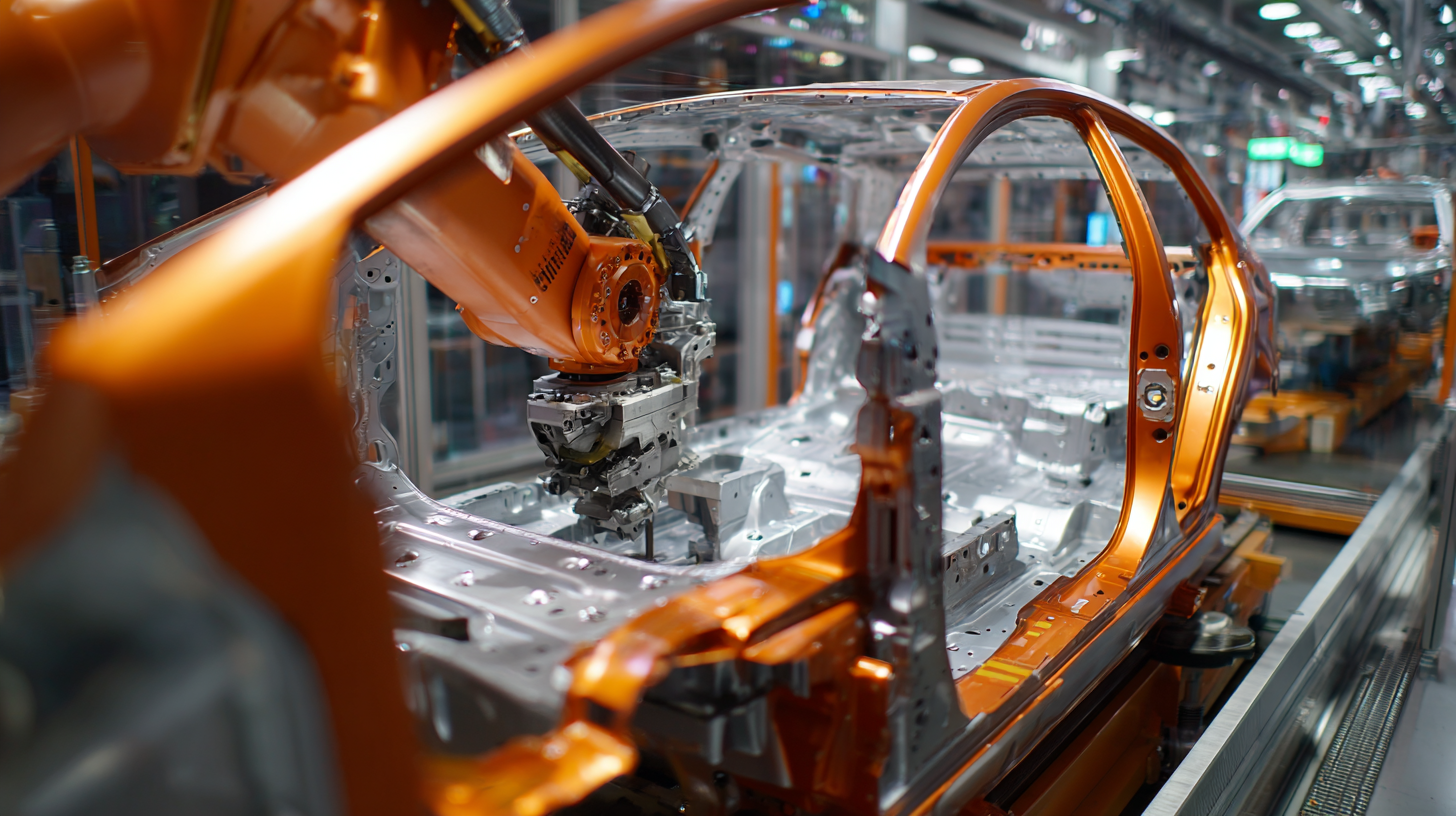

Future Trends: The Role of Automation in Automotive Injection Molding Strategies

The automotive industry is rapidly evolving, with automation playing a crucial role in the transformation of injection molding strategies. As the global injection molding machine market is projected to grow at a CAGR of over 4.8% from 2024 to 2032, it's evident that integrating advanced technology is essential for manufacturers looking to enhance efficiency and meet increasing demand. Automated solutions not only streamline production processes but also improve quality control, thereby reducing waste and operational costs.

Tips for implementing automation in injection molding include investing in smart machinery that utilizes data analytics for real-time monitoring and adjustments. Additionally, collaborating with technology providers can facilitate smoother transitions and offer insights on the latest trends and tools in the market. Emphasizing employee training on these new technologies is also critical; a skilled workforce will ensure that automation is leveraged effectively for optimal results.

Moreover, as automotive suppliers must adapt to chaotic changes in the market, adopting flexible manufacturing practices through automation allows for rapid reconfiguration of production lines. By embracing these innovations, companies can position themselves to not only respond to current trends but also anticipate future demands in an ever-changing landscape.