Exploring Innovations in Automotive Injection Molding at the 138th Canton Fair 2025

As the global automotive industry continues to evolve, the demand for innovative manufacturing techniques remains at the forefront of development. Automotive injection molding, a critical process in vehicle production, has been significantly enhanced by advancements in materials technology and process efficiency. According to the "Automotive Injection Molding Market Analysis" report by Mordor Intelligence, the market is expected to grow at a CAGR of 6.5% from 2021 to 2026, driven by the rising need for lightweight components and the increasing adoption of electric vehicles. The 138th Canton Fair in 2025 will showcase a plethora of innovations in automotive injection molding, highlighting cutting-edge technologies and sustainable practices that are reshaping the industry. This event serves as a pivotal platform for industry leaders to explore the latest trends, network with key stakeholders, and foster collaborations that can propel the automotive sector towards a more sustainable and efficient future.

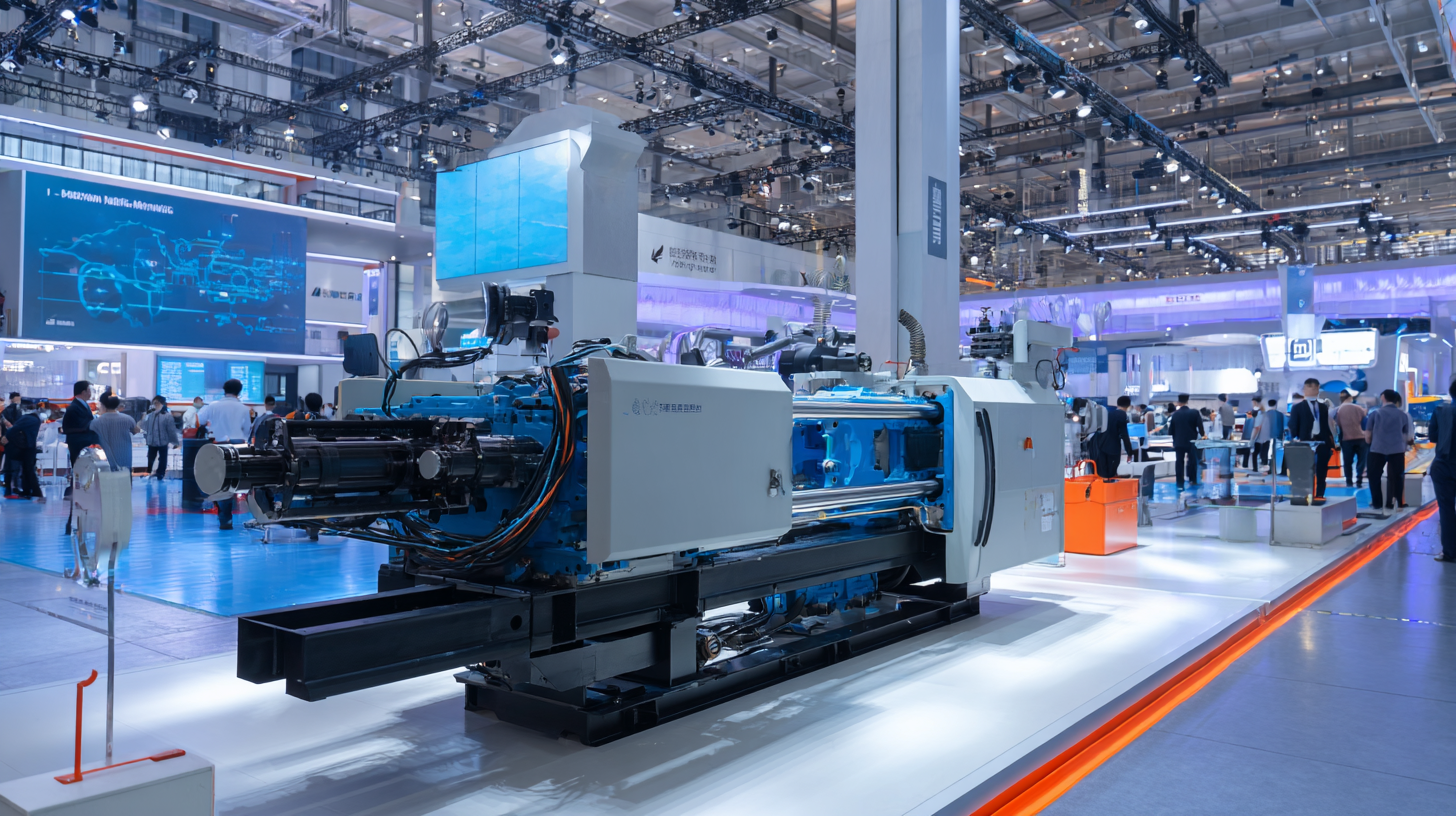

Innovative Technologies in Injection Molding for Automotive Applications

At the 138th Canton Fair 2025, the spotlight on innovative technologies in injection molding for automotive applications promises to revolutionize the industry. With the automotive sector striving for greater efficiency and sustainability, advanced injection molding techniques are gaining traction. A recent report by MarketsandMarkets predicts that the global automotive injection molding market will reach approximately $19.5 billion by 2026, growing at a CAGR of 4.5% from 2021. This growth is largely driven by the increasing demand for lightweight components, which are vital for enhancing fuel efficiency and meeting stringent emission regulations.

The fair will showcase cutting-edge technologies such as multi-material injection molding and 3D printing integration, enabling manufacturers to produce complex parts with reduced cycle times. These innovations not only improve the performance and aesthetics of automotive components but also contribute to significant cost savings. For instance, a joint study by the Society of Plastics Engineers highlighted that implementing advanced injection molding processes can reduce material wastage by up to 30%, underscoring the importance of sustainability in modern automotive production methodologies. As industry leaders gather to share insights at the fair, the focus on these innovative technologies heralds a new era for the automotive manufacturing landscape.

Sustainable Practices in Automotive Manufacturing and Injection Molding

The 138th Canton Fair in 2025 is set to be a pivotal platform for showcasing innovations in automotive injection molding, particularly emphasizing sustainable practices. As the automotive industry grapples with the pressing need for environmentally responsible manufacturing, the adoption of sustainable injection molding techniques is becoming increasingly prevalent. According to recent market analysis by Mordor Intelligence, the global automotive injection molding market is expected to grow at a CAGR of 5.6% from 2021 to 2026, driven by innovations that prioritize low environmental impact.

Sustainable practices in automotive manufacturing are not merely a trend; they are critical for compliance with stringent regulations and for meeting consumer demand for greener products. Companies are now investing in bio-based polymers and recycled materials, which considerably reduce carbon footprints. The adoption of energy-efficient processes has also been highlighted in a report by MarketsandMarkets, predicting that advanced injection molding technologies can reduce energy consumption by up to 30%. By integrating these practices, the automotive industry can enhance the lifecycle management of components while contributing to a more sustainable and circular economy.

Showcase of Cutting-Edge Materials Used in Injection Molding

The automotive industry is witnessing transformative innovations in injection molding, particularly highlighted at the upcoming 138th Canton Fair in 2025. A significant focus will be on cutting-edge materials utilized in injection molding processes, which are pivotal for enhancing the efficiency and performance of automotive components. According to market forecasts, the Linear Injection Molding (LIM) and Liquid Silicone Rubber (LSR) injection machine market is expected to grow from $159.5 million in 2024 to $283.83 million by 2032, achieving a remarkable growth rate of 7.47%. This growth is fueled by the increasing demand for lightweight, durable, and high-performance materials in the automotive sector.

In addition, innovative materials such as C6-LLDPE (Coefficient-6 Linear Low-Density Polyethylene) are gaining traction, with a projected market expansion from 18,835.01 metric tons in 2025 to 25,094.28 metric tons by 2033, reflecting a yearly growth rate of 3.7%. These advanced materials enable manufacturers to produce more efficient and environmentally friendly automotive parts, significantly impacting overall vehicle performance and sustainability. The exhibition at the Canton Fair will provide invaluable insights into these advancements, showcasing how the integration of innovative materials is set to redefine the future of automotive manufacturing.

Impact of Automation on Injection Molding Processes in the Automotive Sector

The automotive sector is undergoing a significant transformation, largely driven by the integration of automation in injection molding processes. As smart manufacturing technologies gain traction, the industry is witnessing a shift toward more efficient and streamlined production methods. According to recent market reports, the global plastic injection molding market was valued at approximately USD 12.67 billion in 2024 and is projected to grow to USD 18.22 billion by 2033. This growth highlights the rising demand for innovative manufacturing solutions that enhance productivity and reduce costs.

Automation technologies are particularly impactful in the injection molding sector, as they minimize labor-intensive tasks and mitigate error rates. The transition to automated systems not only speeds up the production process but also leads to a more consistent quality in the final products. Furthermore, advancements in artificial intelligence are paving the way for data-driven decision-making, enabling manufacturers to optimize their processes in real-time. The injection molding machine market is anticipated to grow at a CAGR of 4.8% from 2025 to 2034, reflecting the increasing adoption of automated solutions that cater to the evolving needs of lightweight auto components and sustainable packaging.

Collaborative Opportunities Between Innovators and Manufacturers at the Fair

At the upcoming 138th Canton Fair in 2025, the focus on collaborative opportunities between innovators and manufacturers in the automotive injection molding sector is set to redefine industry standards. Collaborative innovation is critical, similar to trends observed in the pharmaceutical sector where partnerships across public and private sectors have been identified as both barriers and enablers of transformative advancements. Reports show that such collaborations can reduce development times by up to 30%, highlighting the potential for significant efficiency boosts within automotive manufacturing.

The automotive industry is increasingly recognizing that radical collaboration can lead to groundbreaking innovations. For instance, partnerships among universities, research institutions, and manufacturers are being promoted to harness fresh ideas and leverage technical expertise. The dialogue at the Canton Fair will not only showcase advancements in injection molding technologies but also emphasize sustainable practices. Data suggests that collaborative sustainability initiatives have been shown to enhance operational efficiencies by as much as 20%, paving the way for a greener future in automotive manufacturing. By creating a robust ecosystem of cooperation, stakeholders can position themselves favorably in a rapidly evolving marketplace.

Innovations in Automotive Injection Molding at the 138th Canton Fair 2025

This chart illustrates the distribution of key innovations in automotive injection molding that are expected to be showcased at the 138th Canton Fair in 2025. Each category represents a technological advancement with varying degrees of emphasis among industry participants.

Related Posts

-

Innovative Examples of Automotive Injection Molding Applications in the Industry

-

Solutions for Advanced Automotive Injection Molding Techniques

-

How to Identify Top Suppliers for Optimal Injection Molding Mold Design

-

In Depth Comparison of Plastic Injection Mold Tooling Techniques and Their Industry Impact

-

Common Issues in Achieving the Best Plastic Injection Mold Design

-

Mastering Precision Tooling Techniques for Maximum Efficiency and Quality