Ultimate Guide to Identifying Top Quality Suppliers in Plastic Manufacturing

In the rapidly evolving landscape of plastic manufacturing, selecting high-quality suppliers has become a critical factor for success in achieving superior product outcomes and ensuring operational efficiency. According to the Plastics Industry Association, the U.S. plastics manufacturing sector contributed approximately $382 billion to the economy in 2020, underscoring the importance of sourcing reliable suppliers to maintain competitiveness. As the demand for innovative plastic solutions continues to surge, particularly in sectors such as automotive, aerospace, and consumer goods, businesses must prioritize supplier identification to navigate complex market dynamics effectively. This ultimate guide will explore essential strategies for identifying top-quality suppliers in plastic manufacturing, enabling companies to enhance their supply chain resilience and drive sustainable growth in an increasingly competitive marketplace.

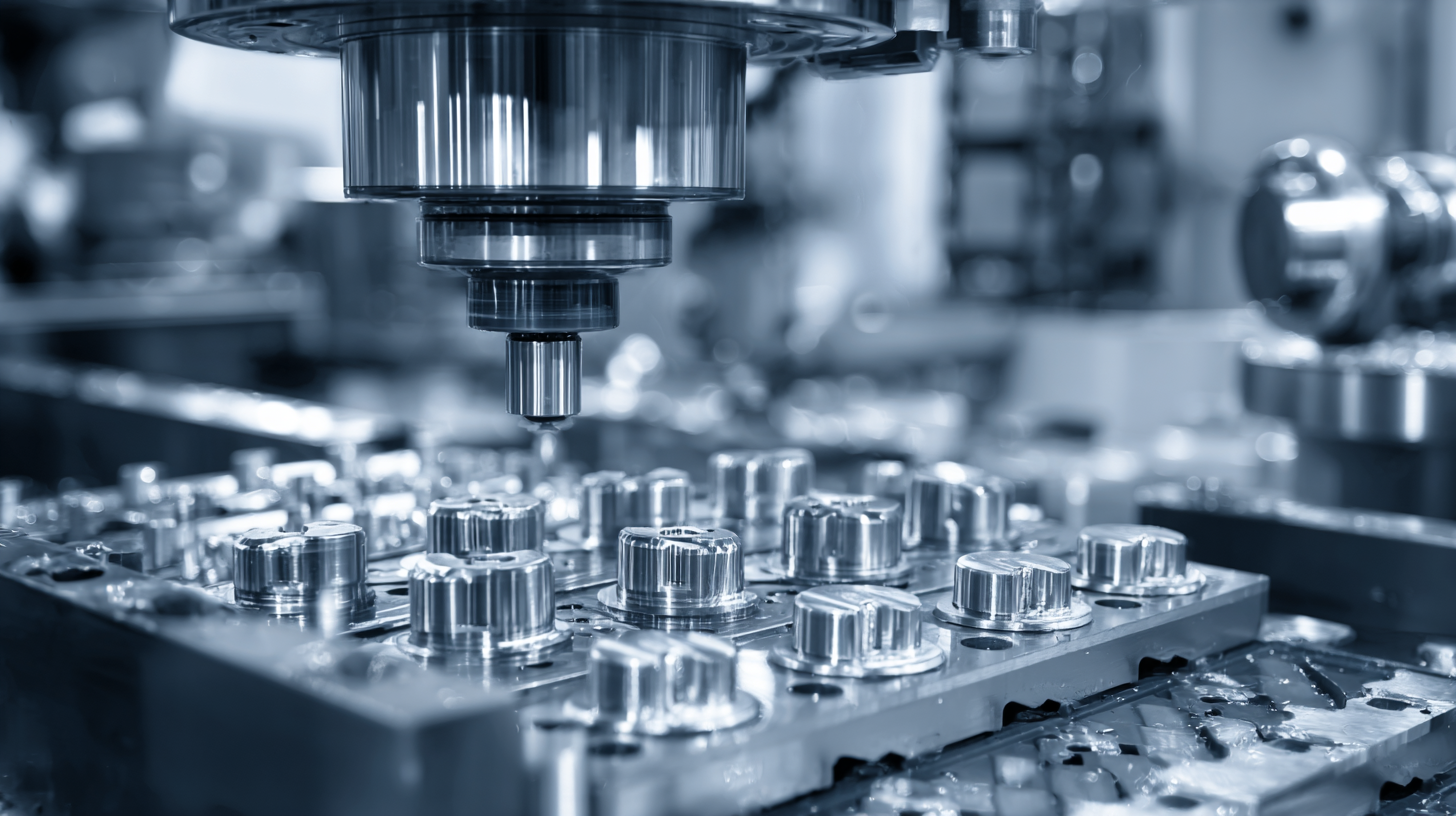

Understanding the Evolution of Plastic Manufacturing Technologies by 2025

In the ever-evolving landscape of plastic manufacturing, identifying top-quality suppliers by 2025 will hinge significantly on understanding the global megatrends that shape the industry. As technologies advance, the integration of connected systems and materials science plays a crucial role in driving decision-making processes. One of the pivotal trends is the shift towards sustainable practices, with manufacturers prioritizing eco-friendly materials and processes that reduce their carbon footprint. This evolution will require suppliers to demonstrate compliance with green standards and offer innovative solutions.

Tips for assessing potential suppliers include examining their investment in technology and sustainability. Look for suppliers that utilize advanced manufacturing techniques, such as additive manufacturing, which not only enhances material properties but also allows for customizable production runs. Another critical factor is their adaptability to market trends, including genetic engineering advancements that improve resource efficiency and production capabilities. Suppliers that are forward-thinking, agile, and aligned with current innovations will stand out as key partners in this transformative era. Advanced technologies will not only shape production but also influence market dynamics and customer preferences, making it essential to choose suppliers who are ready for tomorrow’s demands.

Ultimate Guide to Identifying Top Quality Suppliers in Plastic Manufacturing - Understanding the Evolution of Plastic Manufacturing Technologies by 2025

| Supplier Type | Technology Used | Production Capacity (tons/year) | Quality Certification | Lead Time (weeks) | Geographic Focus |

|---|---|---|---|---|---|

| Injection Molding | Computerized Injection | 1000 | ISO 9001 | 4 | North America |

| Blow Molding | Stretch Blow Molding | 2000 | ISO 13485 | 6 | Europe |

| Thermoforming | Vacuum Forming | 1500 | ISO 14001 | 5 | Asia |

| 3D Printing | Fused Deposition Modeling | 500 | ASTM D638 | 3 | Global |

| Rotational Molding | Single and Double Rotational | 800 | ISO 9001 | 7 | South America |

Key Metrics for Evaluating Supplier Quality in Plastic Production

When evaluating suppliers in the plastic manufacturing industry, several key metrics can help in identifying top-quality partners. First and foremost is the supplier's quality management system. A robust quality management system, such as ISO 9001 certification, not only demonstrates adherence to industry standards but also shows a commitment to continuous improvement. This approach ensures that the supplier can consistently meet specifications and maintain high product quality.

Another critical metric is the supplier's production capacity and lead times. Understanding their ability to scale production while meeting deadlines is vital for ensuring your supply chain remains uninterrupted. Additionally, examining the supplier's track record for on-time delivery provides insights into their reliability and operational efficiency. Lastly, evaluating the supplier's material sourcing practices and sustainability efforts can reveal their commitment to ethical and environmentally friendly practices, which is increasingly important in today’s market.

By focusing on these metrics, businesses can effectively assess and select suppliers that align with their quality and operational goals.

Innovative Practices for Sustainable and Efficient Plastic Manufacturing

In today's rapidly evolving landscape of plastic manufacturing, sustainable and efficient practices are crucial for maintaining competitiveness and relevance. By 2050, as the global population is projected to reach nearly 9.8 billion, the demand for natural resources will skyrocket, necessitating a significant shift towards sustainable production methods. This urgency is echoed in the growing consumer preference for environmentally friendly products, with a survey revealing that 79% of consumers are inclined towards sustainable shopping.

Innovative technologies such as artificial intelligence are key drivers in enhancing sustainability within the industry. Companies are increasingly adopting smart manufacturing solutions, which facilitate efficient operations and waste reduction.

For instance, reports indicate that transitioning to high-performance, eco-friendly materials can achieve substantial reductions in greenhouse gas emissions, aligning with the goals set forth in the United Nations Sustainable Development Goals.

Furthermore, the global ABS market is anticipated to grow from $28.97 billion in 2024 to $41.72 billion by 2031, indicating a robust demand for recyclable and sustainable plastic alternatives.

As suppliers streamline their practices and integrate green technologies, the overall industry impact could lead to significant advancements in environmental health and resource management.

Comparative Analysis of Supplier Capabilities in the Plastic Industry

In the plastic manufacturing industry, understanding supplier capabilities has become crucial for companies seeking to enhance their competitive edge. A comparative analysis of suppliers reveals significant trends impacting the market, including the notable growth of the flexible plastic packaging sector. This market surged from USD 190.71 billion in 2023 to USD 199.46 billion in 2024, with a projected CAGR of 5.01% through 2030. Such dynamics necessitate a careful evaluation of suppliers’ technological competencies and their ability to innovate in response to market demands.

Additionally, the integration of advanced methodologies such as Six Sigma and machine learning into plastic manufacturing processes has shown potential for optimizing operations and reducing defects. A recent study highlights how embracing these tools can significantly enhance quality control, ultimately leading to more efficient production cycles. As the industry grapples with sustainability challenges and the push towards chemical recycling, suppliers who invest in these innovative practices will likely emerge as leaders in the competitive landscape, proving their capability to adapt and thrive amidst evolving market conditions.

Strategic Techniques for Building Long-term Supplier Relationships in Plastics

Building long-term supplier relationships is essential for any business operating in the plastics manufacturing industry. As companies strive to achieve sustainability goals, such as the ambitious carbon neutrality strategy set for 2045, the focus on selecting high-quality suppliers becomes increasingly important. Strategic techniques for building these relationships can significantly enhance collaboration and innovation, vital for navigating the complex challenges of the industry.

To foster strong partnerships, companies should prioritize transparency and communication. Initiating open dialogue with suppliers about sustainability goals, quality standards, and expectations can create a foundation of trust. Regular assessments and feedback can further strengthen this rapport, ensuring that both parties are aligned in their objectives. Additionally, involving suppliers in the innovation process can provide valuable insights and lead to the development of more sustainable practices and products, which are critical in today’s market landscape.

Furthermore, investing in supplier training and development not only improves product quality but also encourages a shared commitment to sustainability. By equipping suppliers with the necessary skills and knowledge, businesses can enhance their overall supply chain integrity and promote a culture of continuous improvement. This collaborative approach ultimately drives success and fosters resilience in the ever-evolving plastics manufacturing sector.

Supplier Quality Evaluation in Plastic Manufacturing

This bar chart represents the quality scores of various suppliers in plastic manufacturing. A higher score indicates better quality performance, which is crucial for building long-term supplier relationships.