How to Identify Top Suppliers for Optimal Injection Molding Mold Design

In the competitive landscape of manufacturing, the significance of effective mold design for injection molding cannot be overstated. As the global injection molding market is projected to reach USD 300 billion by 2025, optimizing mold design is pivotal for enhancing production efficiency, reducing costs, and improving product quality. Research indicates that approximately 70% of product quality is determined during the design phase, making the selection of top suppliers critical. An optimal mold design not only ensures precision and durability but also accelerates time-to-market. Therefore, identifying reliable suppliers who specialize in mold design for injection molding is essential for companies striving to maintain a competitive edge in this fast-evolving industry. With the right partnerships, manufacturers can leverage cutting-edge technologies and innovations that drive sustainable growth and efficiency.

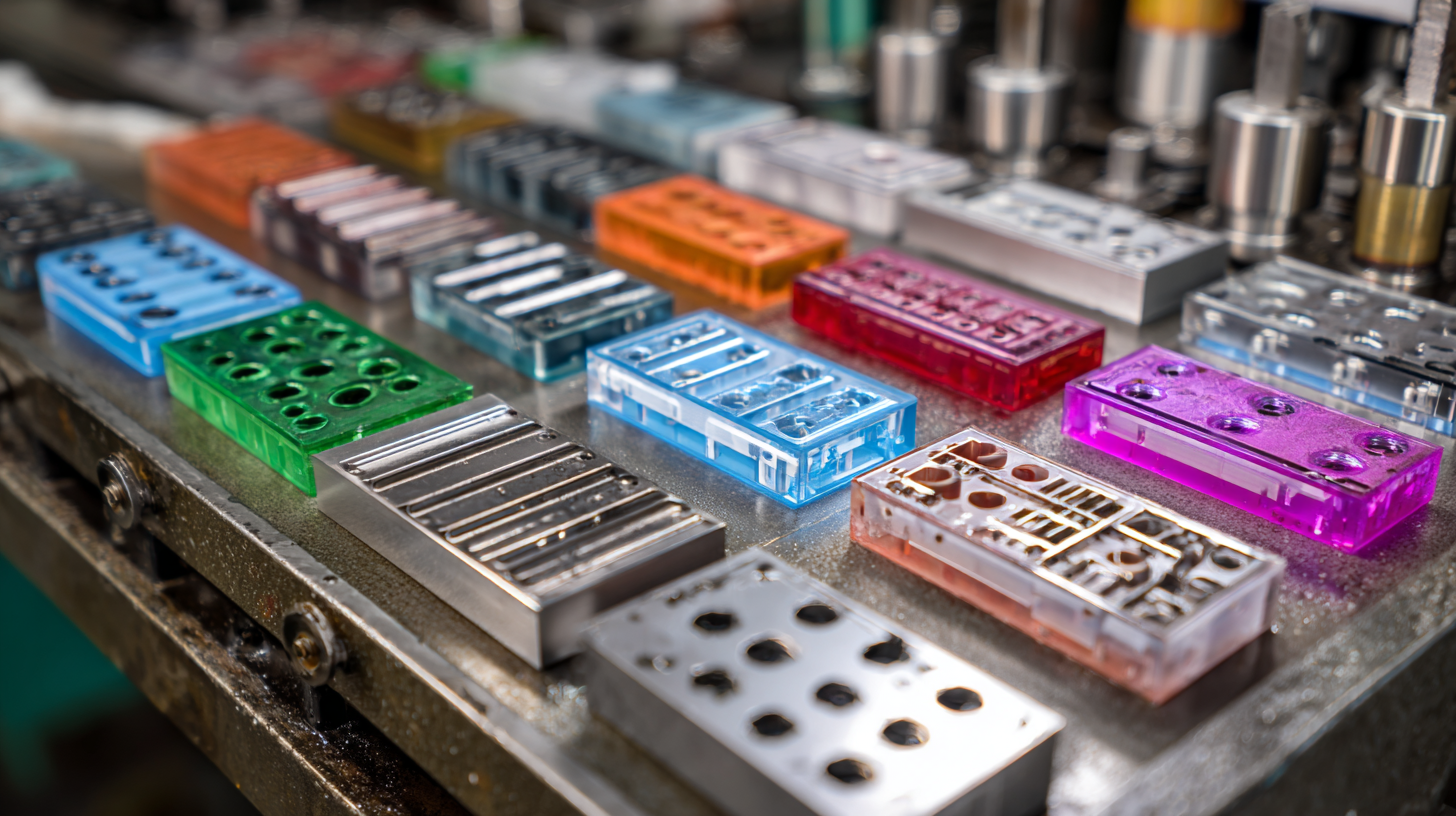

Understanding the Unique Characteristics of Various Product Types in Injection Molding

When selecting suppliers for injection molding, it's crucial to understand the diverse characteristics of the products you're designing. Different materials and designs will significantly influence your molding process. For instance, high-temperature plastics may require specialized mold designs and cooling systems, while flexible materials might need different cavity shapes to avoid deformation. By recognizing these unique requirements, you can better communicate with potential suppliers, ensuring they possess the necessary expertise.

Tip: Always evaluate the supplier's experience with specific materials and product types relevant to your project. Request case studies that highlight previous projects to assess their capabilities in handling similar challenges.

Additionally, product complexity can affect the supplier's ability to meet your design specifications. Intricate designs may necessitate advanced machinery or meticulous machining processes. Make sure to inquire about the supplier’s technology and how they plan to ensure precision in their mold designs.

Tip: Schedule visits to their facilities if possible. Observing their operations first-hand will give you insight into their craftsmanship and commitment to quality, enabling you to make a more informed decision.

Top Suppliers for Optimal Injection Molding Mold Design

This chart illustrates the ratings of various top suppliers for injection molding mold design, highlighting their performance in a competitive market based on various product types and characteristics.

Key Factors Influencing Supplier Selection for Diverse Injection Mold Designs

When selecting suppliers for injection molding mold design, various key factors play a critical role in ensuring optimal production outcomes. First and foremost, supplier expertise in specific mold configurations is paramount. According to a report by MarketsandMarkets, companies that partner with suppliers possessing specialized knowledge in niche mold designs experience a 20% decrease in production time. This expertise not only speeds up the process but also enhances the quality of the final product.

Another crucial factor is technological capabilities. Suppliers equipped with advanced technologies such as 3D printing and simulation software can deliver molds that better meet specific design requirements. A survey conducted by Grand View Research indicates that 65% of manufacturers prioritize suppliers who invest in the latest technologies, as it significantly influences the efficiency and precision of the manufacturing process.

Tips: When evaluating potential suppliers, consider conducting a performance audit to assess their previous projects and client feedback. Additionally, look for suppliers who offer prototyping services, as this can streamline the design process and reduce the risk of costly errors during production. Remember, the right supplier can make a significant difference in both cost-efficiency and product quality.

Evaluating the Impact of Material Properties on Mold Design Efficacy

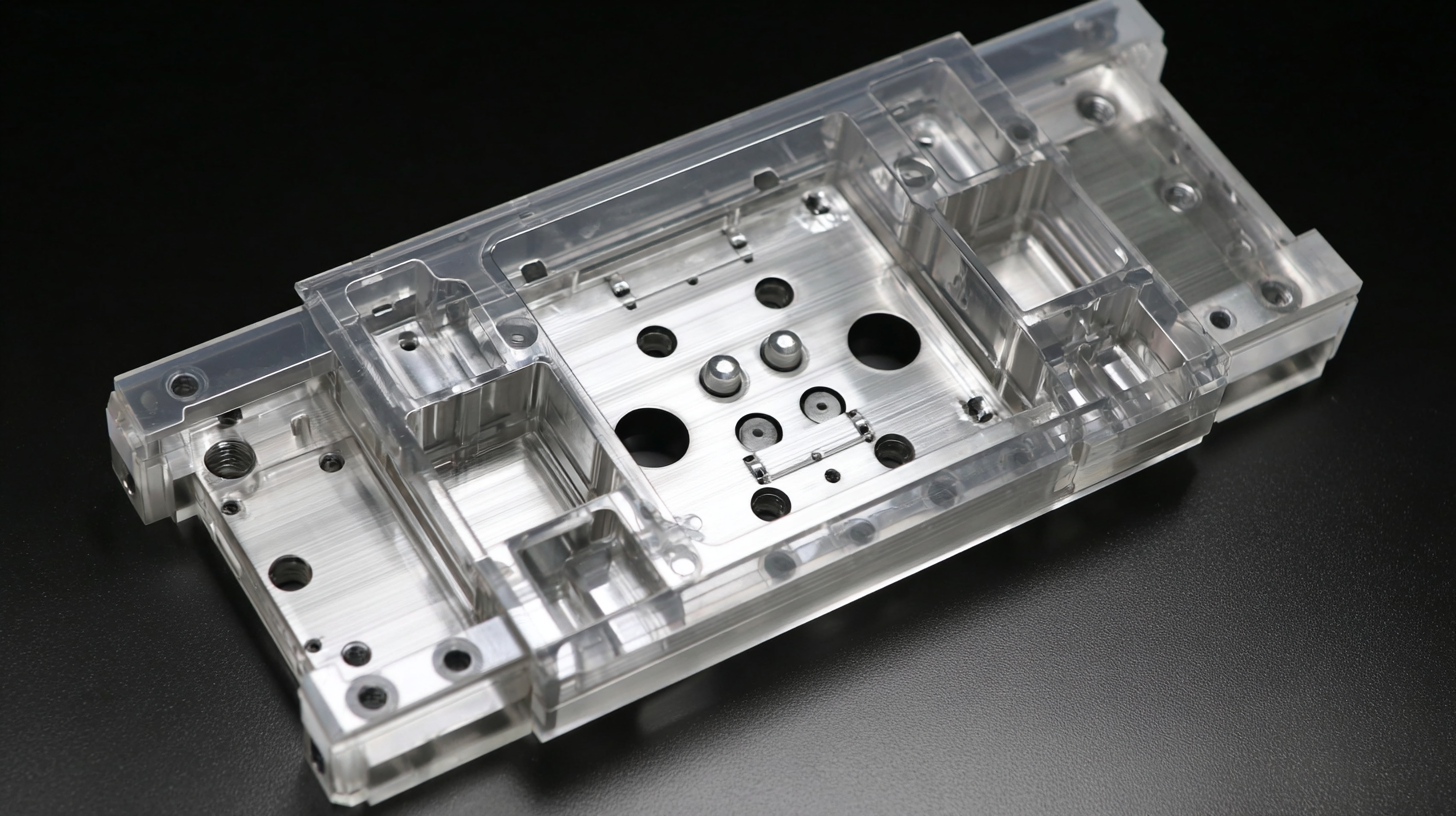

When it comes to injection molding, the material properties of the plastics used play a critical role in determining the success of mold design. Different materials exhibit varying characteristics such as flowability, thermal stability, and shrinkage, which directly influence how molds are engineered. For instance, materials with high flowability can fill intricate mold cavities with ease, enabling detailed geometries that enhance the final product’s functionality and aesthetics. Conversely, materials that exhibit high shrinkage rates necessitate adjustments in mold design to ensure dimensional accuracy and prevent defects.

Additionally, understanding the thermal properties of the chosen material is essential for optimal mold design efficacy. Different plastics have varying melting temperatures and cooling rates, influencing the cycle times during the manufacturing process. A thorough evaluation of these thermal behaviors allows engineers to design molds that facilitate effective heat transfer, ultimately improving production efficiency. By carefully considering the interplay between material properties and mold design, manufacturers can ensure higher quality outputs and reduce costly errors, establishing a solid foundation for successful injection molding operations.

How to Identify Top Suppliers for Optimal Injection Molding Mold Design - Evaluating the Impact of Material Properties on Mold Design Efficacy

| Supplier Assessment Criteria | Material Type | Material Properties | Impact on Mold Design |

|---|---|---|---|

| Supplier A | Polycarbonate | High Impact Resistance | Excellent for complex mold designs |

| Supplier B | ABS | Good Strength and Rigidity | Moderate design versatility |

| Supplier C | Nylon | High Durability and Toughness | Suitable for heavy-duty applications |

| Supplier D | Polypropylene | Chemical Resistance | Ideal for automotive applications |

| Supplier E | Acetal | Low Friction and Wear | Great for precision components |

Analyzing Industry Standards and Best Practices for Supplier Performance

When it comes to selecting top suppliers for injection molding mold design, understanding industry standards and best practices is crucial. First, suppliers should be evaluated against relevant industry certifications such as ISO 9001 or IATF 16949. These certifications demonstrate a commitment to quality management systems and ensure that suppliers adhere to rigorous processes that lead to consistent product quality. Monitoring compliance with these standards helps in mitigating risks associated with supplier performance and reliability.

In addition to certifications, assessing a supplier's track record through case studies and client testimonials can provide insight into their capabilities. Consider how well they adapt to industry trends, such as adopting advanced manufacturing techniques or utilizing sustainable practices. Analyzing these factors not only highlights a supplier’s operational efficiency but also their willingness to innovate, which can significantly affect the performance of injection molds. Engaging in transparent communication with potential suppliers further enhances this analysis, allowing for a deeper understanding of their processes and how they align with your project goals.

Leveraging Advanced Technologies for Optimal Mold Design Across Product Categories

In the quest for optimal mold design across various product categories, leveraging advanced technologies has become paramount. Recent advancements in the overmolding process have showcased the integration of nano and micron-scale reinforcements in both thermoset and thermoplastic composites. This evolving landscape allows for the creation of composite systems that not only enhance performance characteristics but also enable innovative design solutions tailored to specific applications. Such breakthroughs are essential for manufacturers aiming to push the boundaries of mold capabilities in diverse markets.

Additionally, the rise of intelligent design systems driven by deep semantic understanding transforms the traditional approaches to mold design. By utilizing data-driven techniques, companies can significantly reduce inefficiencies and error rates associated with complex design processes. These systems promote a nuanced understanding of materials and interactions, fostering the development of multi-material additive manufacturing techniques that expand design possibilities. As the industry continues to explore these innovative strategies, the focus on sustainability through the production of 3D cellulose-based materials for packaging is also gaining traction, further underscoring the need for advanced mold design methodologies aligned with modern demands.